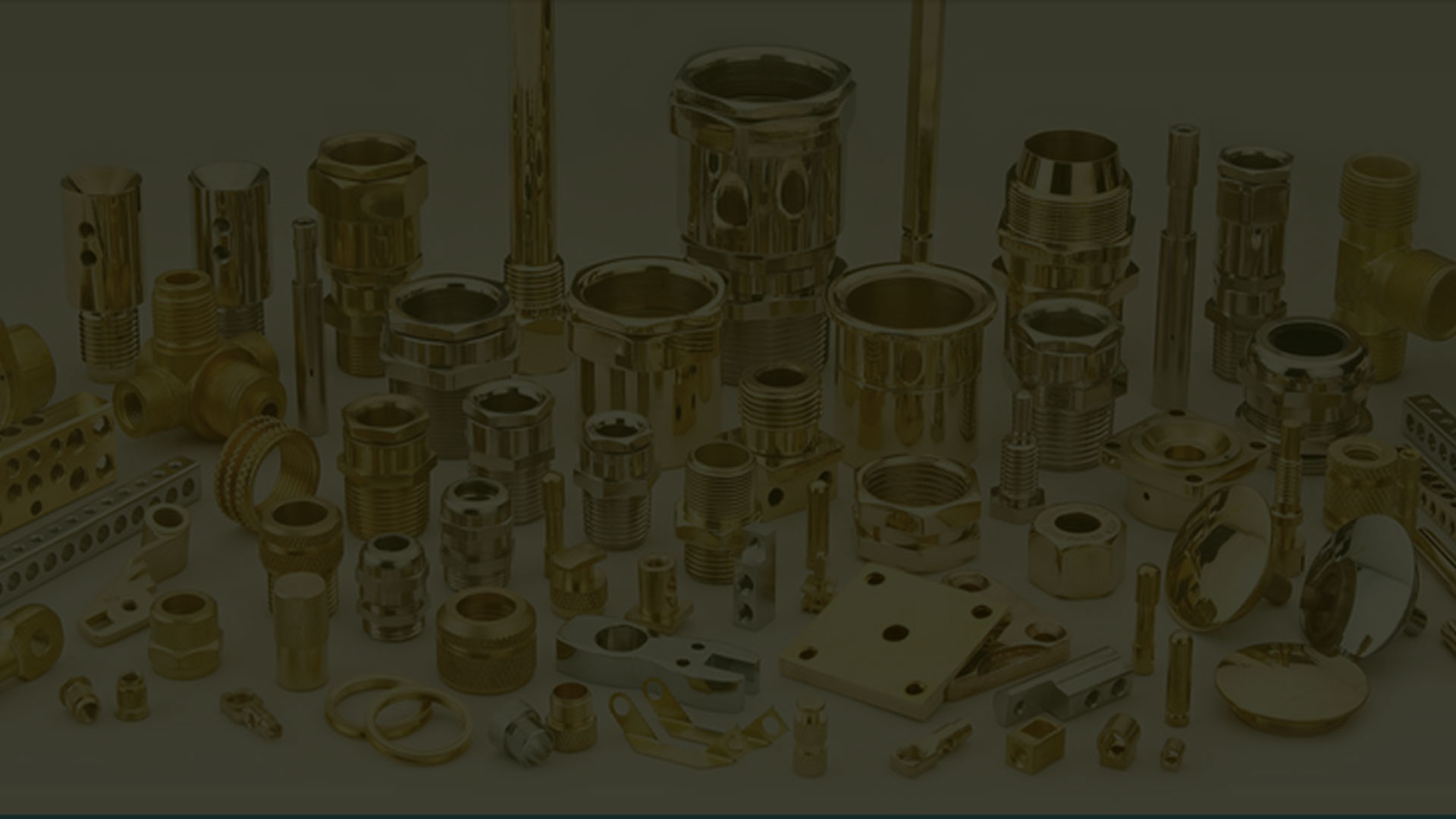

Best Quality of Brass Compnents Delivered By "Tilara Brass Component" Company

We are one of leading Brass Parts Manufacturer in Jamnagar for high Quality Brass metal. Brass Parts made by us do not get affected by water or moisture and thus do not rust. Produced using the good quality of brass raw material for durable nature. These filters are very helpful and work very smoothly. Entire range of the Brass Parts are made using advance technologies.

Process Details

Purchase of Raw Material

First step of production is to purchase the raw material (Brass Rods) form our trusted and verified supplier. Material are to be purchased as per the standard material grade or customer's specification as below.

Free Cuttings 319/89Grade-1, IS 319/89-Grade-2, IS 319/89 Grade-3, BS 2874-CZ 121 Pb3, EN 12164:1998, DIN 17660.

Forging Brass Rods BS 218, DIN 17660, IS- 6912/2005 FLB, IS-8737

Leaded Free Brass for Sections BS 2874-CZ 130, IS 4170/67-CuZn40, IS 4413/81- CuZn37

Riveting Brass Wires (Leaded) IS 2704/83-Cunz35pb1.

Naval Brass Rods IS 291/89 – Grade 1, IS 291/89 – Grade 2.

Quality checking of material

Before start a production it is very essential to verify material grade report provided by supplier. In this process technician (Quality Supervisor) is responsible to verify the material grade and also confirm that everything is as per customer's specifications. Once got approval from Quality supervisor material send for the further manufacturing process

Manufacturing

Here in this step manufacturing process are likely to be- Threading, Drilling, Facing, milling and cutting. In this process expert engineers are responsible for taking care of measurement, dimensions and quality checking of products.

Our experienced & expert engineers has been producing in tolerance between ±0.02 mm to ±0.05 mm and also it may in micron

Quality Control Department

After product produced, it has been send to QC Department. Quality Control Supervisor will check all dimensions and Measurements on the basis of various quality checking methods i.e. statistical quality control (SQC), Simple Random and Systematic Random Sampling Methods, Statistical Process Control (SPC) etc., and generates the report. If reports are under required tolerance then material will send to packing department otherwise it will send for reproducing process

Packaging

Within the scope of picking each order or suborder are directed to a particular packing location. The completeness of whole order can be checked here optionally. Than the packing list gets printed to be included into the packing and the whole order is packed